PLAY FOR TODAY, PLAY FOR TOMORROW: THE SHIFT TOWARD ECO-FRIENDLY TOYS AND SUSTAINABLE PRODUCTION

This article originally appeared in the September/October 2019 issue of the Toy Book.

Just five years ago, the LEGO Group found itself in a sticky situation. Its decades-long partnership with Royal Dutch Shell — the Shell Oil Co. in the U.S. — had come under fire by an environmental group, targeting the Danish toymaker and its famous bricks in a campaign touting a message that said “everything’s not awesome.” LEGO President and CEO Jørgen Vig Knudstorp quickly fired back, issuing a short-but-stern statement denouncing the campaign for using LEGO as a tool to target Shell, while doubling down on LEGO’s commitment to children and play.

The public scuffle was a temporary irritation for all parties involved, but it did, perhaps, crack the door open to start shining a light on some serious issues that the greater toy industry might have been avoiding for a while. It was also an issue that LEGO was already in the process of addressing: The production of toys is a resource-intensive endeavor that leaves behind a lot of waste, not just during production, but long after the toys make their way into — and out of — consumers’ homes.

Less than a year later, the LEGO Group took a massive step toward something that had been in the works since 2012. The LEGO Sustainable Materials Centre was born, and in turn, so was the true beginning to an exhaustive search for sustainable materials to replace the long-used, petroleum-based materials that the company had been using in its bricks and other toys for decades.

At the time, LEGO Group owner (via KIRKBI A/B) and former President Kjeld Kirk Kristiansen hailed the substantial investment in sustainability as “a testament to [the] continued ambition to leave a positive impact on the planet, which future generations will inherit.”

For LEGO, as with other toymakers, the “eco-friendly” and “sustainable” catchphrases needed to translate into something tangible, with one major problem being that the very definition of “sustainable” was — and still is — very much up for debate. The challenge is complex, balancing not only the materials used in products, but also the natural resources and energy used in their creation, the feasibility of recycling waste, an overhaul in how the products are packed and shipped, and the thought put into the inevitable end of life for the toys.

Within just two years, the LEGO Group began running on 100% renewable energy — three years ahead of schedule — and was making progress toward its goal of using completely sustainable materials in its packaging by 2025 — and its products by 2030. Since then, the company has partnered with the World Wildlife Fund and its Bioplastic Feedstock Alliance in an effort to develop sourcing and demand for bioplastics. By last year, the first LEGO pieces crafted from plant-based polyethylene hit the market — appropriately, the green “botanical” elements of LEGO sets, such as trees, bushes, and other greenery.

ENTER THE LEGO TREEHOUSE

Released this August, the LEGO Ideas Treehouse was born from an idea that spawned before plant-based LEGO pieces even hit the market. Designed by Kevin Feeser and pitched in 2017 through the LEGO Ideas crowdsourcing platform, the LEGO Treehouse has come to market as a set that includes 185 botanical elements made from plant-based polyethylene plastic using sustainably sourced sugar cane.

“When I first saw the model, I was blown away. Not only because it looks amazing, but also because it connects strongly to the very reason we are investing so much time and effort in identifying new and sustainable materials, which is to preserve natural resources and fulfill our planet promise,” says Tim Brooks, vice president of environmental responsibility of the LEGO Group.

And not only is the LEGO Treehouse filled with lush greenery, but it also comes with autumn leaves as well.

HOMEGROWN BIOPLASTICS AND RECYCLED MILK JUGS

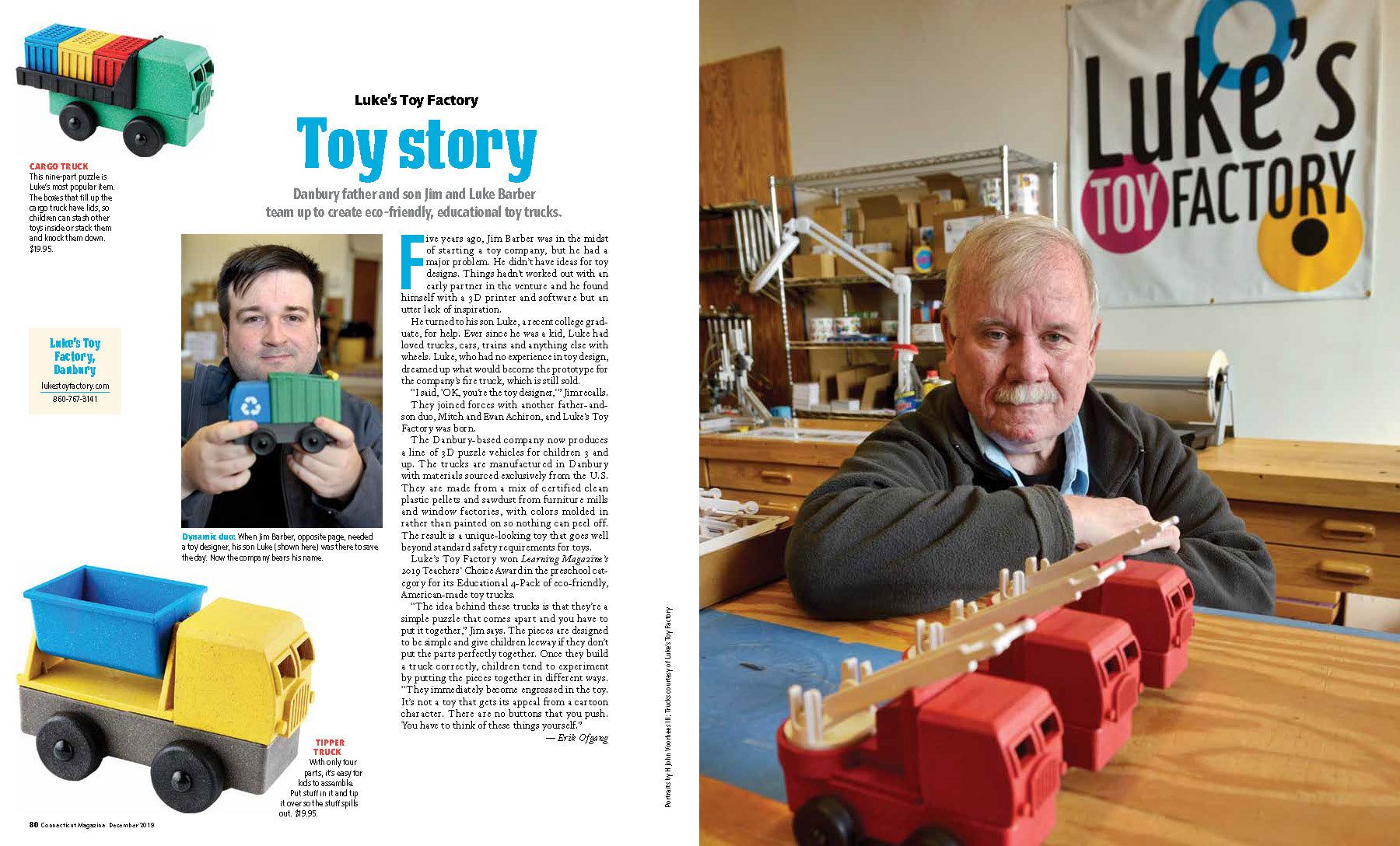

It was the lead paint crisis of 2007, in which millions of toys manufactured in China were recalled in the U.S. after tests showed unsafe levels of lead, that inspired professional photographer Jim Barber to investigate the toys that his own kids had once played with. His goal was to develop new, safe toys that could be manufactured in America using sustainable methods. In 2014, after years of researching the possibilities of creating toys using a wood-and-plastic mix similar to that used in the manufacturing of composite decking materials, Barber and his son, Luke, launched their first Kickstarter campaign, successfully funding their first toy: a firetruck.

Today, Luke’s Toy Factory manufactures a full range of toys in Connecticut while sourcing materials from other states, including maple sawdust reclaimed from furniture mills in North Carolina and a wood-plastic mixture from Michigan. Its Classic collection features toys that are molded in color, rather than it being painted on, and each toy — which is also a 3D stacking puzzle — contains 30% less plastic than a traditional toy truck in this scale.

“For us, the materials that we use in a toy — and its packaging — drives our approach to sustainability,” Barber says. “Safety is the first and most important factor. We need to know exactly what is in the raw materials, which can be challenging with organic inputs.”

In recent months, Luke’s Toy Factory has increased the variety of organic materials that it uses. The company rolled out two line extensions beyond its Classic line, including Naturals and Hybrids. The Naturals collection includes coconut shells, flax fiber, rice hulls, and walnut shells in its mixture, while the Hybrids mixes the bright colors of the Classics collection with various fibers from the Naturals line.

In choosing what might work for a toy, Barber says that following safety testing, the ability to use a particular organic material in a toy becomes technical.

“Does the material mold well, color well? What are the technical issues that we may have with this material? This is the same challenge that other toy companies are encountering as they explore sustainable materials, but for us as a startup, it’s been part of the process since day one,” he says.

Now available in more than 250 independent toy stores and specialty shops across the country, Barber says that Luke’s Toy Factory sources locally as much as possible, with a goal of reducing the carbon footprint of its supply chain — a goal shared on the West Coast by Green Toys.

On the other side of the country, Green Toys maintains a tight, local supply chain in its mission to craft high-quality toys and other products. From plastic boats, stacking cups, and wagons created using materials including recycled milk jugs and yogurt containers to board books and toy packaging crafted from 100% recycled paper and cardboard printed with soy ink, the entire workflow of Green Toys keeps raw materials from winding up in landfills.

THE SIXTH “S”

In Sweden, Viking Toys added a sixth “S” to its corporate philosophy, with “sustainable” joining the company mantra, along with safe, soft, simple, silent, and strong. Like LEGO, the company went with a plant-based material for the debut of its Ecoline collection of toys earlier this year. Viking Toys calls its sugar-cane-based material biotylene, and it is sourced from controlled fields in Brazil. Because sugar cane absorbs a high volume of carbon dioxide from the atmosphere, its growth is capable of reducing greenhouse gasses.

Conveniently, should the toy reach its end of life, biotylene is 100% recyclable and can be processed alongside conventional plastics. Gösta Kjellme, founder and CEO of Viking Toys, says that the company is on a mission “to produce toys that are a sustainable alternative and an antidote to the prevailing throwaway culture.”

THE PLUSH REVOLUTION

Earlier this year, two major players in the plush category made big, renewed, and enhanced commitments to changing their materials. In January, Aurora World adopted 100% post-consumer polyester for all of its products. Additionally, the company switched to eco-friendly recycled biopolymer pellets — used to give plush toys weight and the best shelf appearance — for all of its products. In the future, Aurora World plans to use 100% recycled material for hangtags and make changes to its shipping and packaging processes as part of a company-wide environmental overhaul.

For Wild Republic, sustainability is a personal affair that led to the creation of the company’s “Promise to the Planet.” Founder G.B. Pillai and his grandson, Vishunu Chandran, now president of the company, continue to reiterate a commitment to nature and conservation as they work to find new ways to reduce non-biodegradable items while utilizing recycled materials in production and packaging. This summer, Wild Republic launched Ecokins, its first plush line created from 100% recycled materials — and the packaging is eco-conscious, too, with biodegradable polybags and hangtags printed with soy ink.

RECYCLING, TERRACYCLING, CONSUMER CONVENIENCE, AND AWARENESS

One of the biggest problems toymakers face — and that is noticed by parents — is the difficulty in recycling both toys and their packaging waste. The massive popularity of surprise-and-reveal toys certainly lit a fire under parents to call for better waste management, and for MGA Entertainment (MGAE) — makers of L.O.L. Surprise! — the solution was a partnership with a company that already had experience tackling hard-to-process toys: Terracycle.

The vast difference in materials used to create certain toys presents a problem when it comes to sorting and processing. Terracycle can solve that, processing toys to be recycled into new creations, such as park benches, flower pots, and play spaces. The Hasbro Toy Recycling Program launched last year as a way for families to send well-loved toys and games to Terracycle for processing.

Following partnerships with Hasbro and MGAE, ZURU inked a deal this spring to make its Bunch O Balloons 100% recyclable thanks to Terracycle. Now, perhaps the biggest issue is consumer awareness and action, as parents will have to box their waste materials — both packaging and toys — and print shipping labels from the Terracycle website before dropping their boxes off to be shipped back.

COST CONSIDERATIONS AND PACKING THE FUTURE

As the industry continues to shift and evolve, the number of companies increasing their efforts to decrease their footprints is growing, but changing habits takes time — and it isn’t cheap. In fact, the consumer market is starting to drive the future of change, with new parents looking for action faster than some companies can respond.

“As millennial parents are increasingly becoming environmentally conscious, they are actively seeking out sustainable, ethically made products for themselves and their kids,” Luke’s Toy Factory’s Barber adds.

It’s a trend that has led to an uptick in classic, wooden toys, notably appearing frequently in posts from the Instagram influencer crowd.

Producing relatively simple toys, such as bricks or other non-articulated plastics that utilize minimal pieces, using eco-friendly means has become fairly accessible. However, the majority of toys are far more complex and are usually manufactured overseas. That remains a challenge, in addition to the fact that there’s just no common standard for what “eco-friendly” or “sustainable” mean.

Brett Klisch, owner and creative director of Peru Meridian Studios, is a toy designer who regularly consults with manufacturers on their needs and new products. “Every time, the first consideration is cost,” he says. “The biggest barrier to the cost coming down is that the infrastructure of eco-friendly manufacturing practices and materials needs to become as firmly established as the current practices. That way, the prices can balance out.”

In the meantime, the one area in which nearly every company can up its eco-friendly game is packaging, which prompted The Toy Association to begin offering the Disney-developed Smart Packaging Tool as a benefit for its members.

Next year, the industry may have its first look at what a plastics-free packaging future will look like. In August, Hasbro unveiled a plan to begin phasing out the use of plastic packaging in its new product. The initial plan calls for an end to polybags, shrink wrap, window sheets, blister packs, and elastic bands. Hasbro says it hopes to eliminate virtually all plastic in packaging for new products by the end of 2022.

“As designers, we are working on entirely new ideas of what toy packaging can be,” Klisch adds. “The industry needs to be able to evolve into a new paradigm of what can be considered to be acceptable packaging. The old ways were so wasteful.”