Where Are All the Workers?

The team at GW Precision, Inc with the tooling to make the Tipper Truck

By Jim Barber (Luke's Dad), Luke's Toy Factory Managing Partner

A few days ago, we gave a factory tour to two little 5-year-old twins and their dad. Our usual tour involves showing the kids how Luke designs the toys on a computer, then progresses to the 3D printer. After that, we explain how the parts are injection molded at a local factory, delivered to us and then assembled and packaged.

Since 5 year olds have an attention span one minute longer than their age, we were soon inundated with questions:

To Luke: Why did you shave off your beard? (He is pictured on the package with a beard) Answer: “It comes and goes”.

To Luke: Can you design a space ship? Answer: “I already have!” And then he shows the 3D printed mockup.

To Jim: Where are all the workers? “Well, that’s a long answer”, and within 10 seconds they were over gazing at the drill press where Luke drills the holes for the axles and were completely uninterested in the answer.

But it’s an interesting story, and points up what manufacturing in America means to the broader economy.

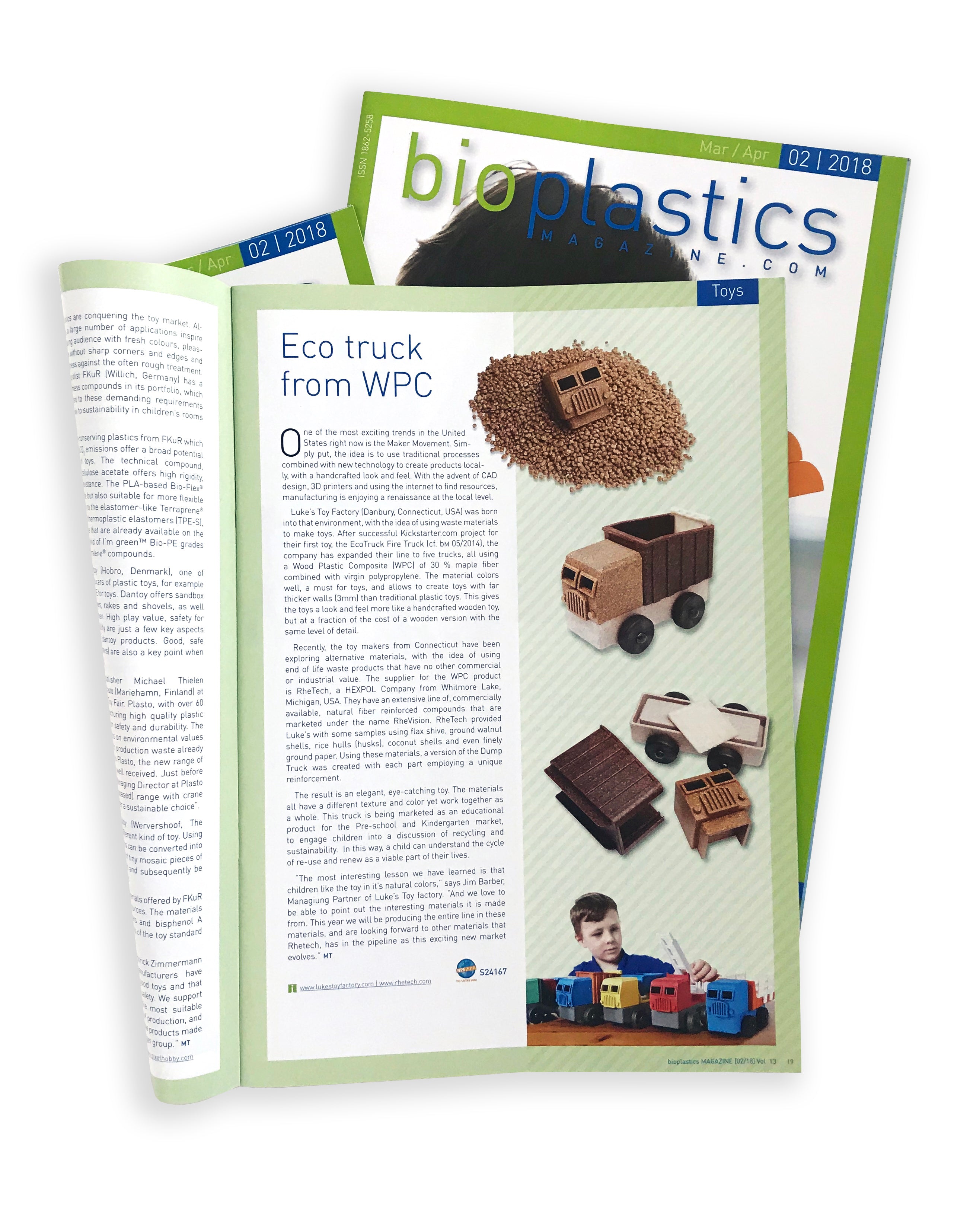

The design and 3D printing is just the beginning. After we test the 3D printed parts with kids, and refine the designs, then it’s time to make the mold. This involves a mold engineer, and skilled mold makers, who carve the molds out of high quality steel. It’s a complicated process that involves a team of people and takes several months. This is done at GW Precision in Deerfield, MA.

Meanwhile, out in faraway Michigan, another factory is hard at work producing our raw materials. This involves taking sawdust from furniture factories and blending it with polypropylene plastic pellets to make a wood plastic composite (WPC). This is then shipped to the injection molding factory, Vanguard Plastics, in Southington, CT.

The mold is delivered to the injection molding factory, where another team of people molds the parts, inspects and packages them for delivery to our facility in Danbury, CT.

While that is going on, Mitch designs the boxes, which are then printed at a company in Milford, CT. He also creates collector’s cards, which go into the box, and a ton of catalogs, mailers and other printed material, most of which is printed in Texas.

All these components arrive at our facility in Danbury, CT, where we drill the chassis, attach the wheels and axles and then assemble the toys. Then they are inserted into the boxes and are ready to ship.

To sell the toys, we have a website, created and maintained by Evan. We also attend numerous trade shows around the country to interest stores and educators in our products.

So, the short answer is that our workers are all over the place, and each one along the way has a hand in making the toys that your child plays with. We like to say that our workers go out to lunch in America, not Beijing. Economists call this the “multiplier effect”, in that each job adds to the overall health and wealth of a community. We think it’s the right thing to do.