Luke's Toy Factory Featured in Bioplastics Magazine

Recently we attended the NPE, (National Plastics Exposition), in Orlando, Florida. This event happens every 3 years. For us, it’s a chance to find new materials and suppliers, in our mission to use more sustainable and eco-friendly materials in our toys.

This year’s NPE was much more focused on sustainability than past shows, as the industry reacts to demand for new ways to help reduce the carbon footprint of the plastics industry. We found some great products- plant based polymers, recycled plastics and a variety of alternative fillers to replace the plastic resin.

We made our own news as well, by introducing a version of our trucks made with a variety of alternative fillers, including Walnut Shells, Rice Hulls and even Coconut Shells.

The industry’s leading publication on this subject is BioPlastics Magazine, published in Europe but read worldwide. The magazine ran a feature article on our new trucks, highlighting the partnership between our company and RheTech, our resin supplier.

The new trucks will be rolling out later this summer.

Below is the full text of the article.

_____________________________________________________

One of the most exciting trends in the United States right now is the Maker Movement. Simply put, the idea is to use traditional processes combined with new technology to create products locally, with a handcrafted look and feel. With the advent of CAD design, 3D printers and using the internet to find resources, manufacturing is enjoying a renaissance at the local level.

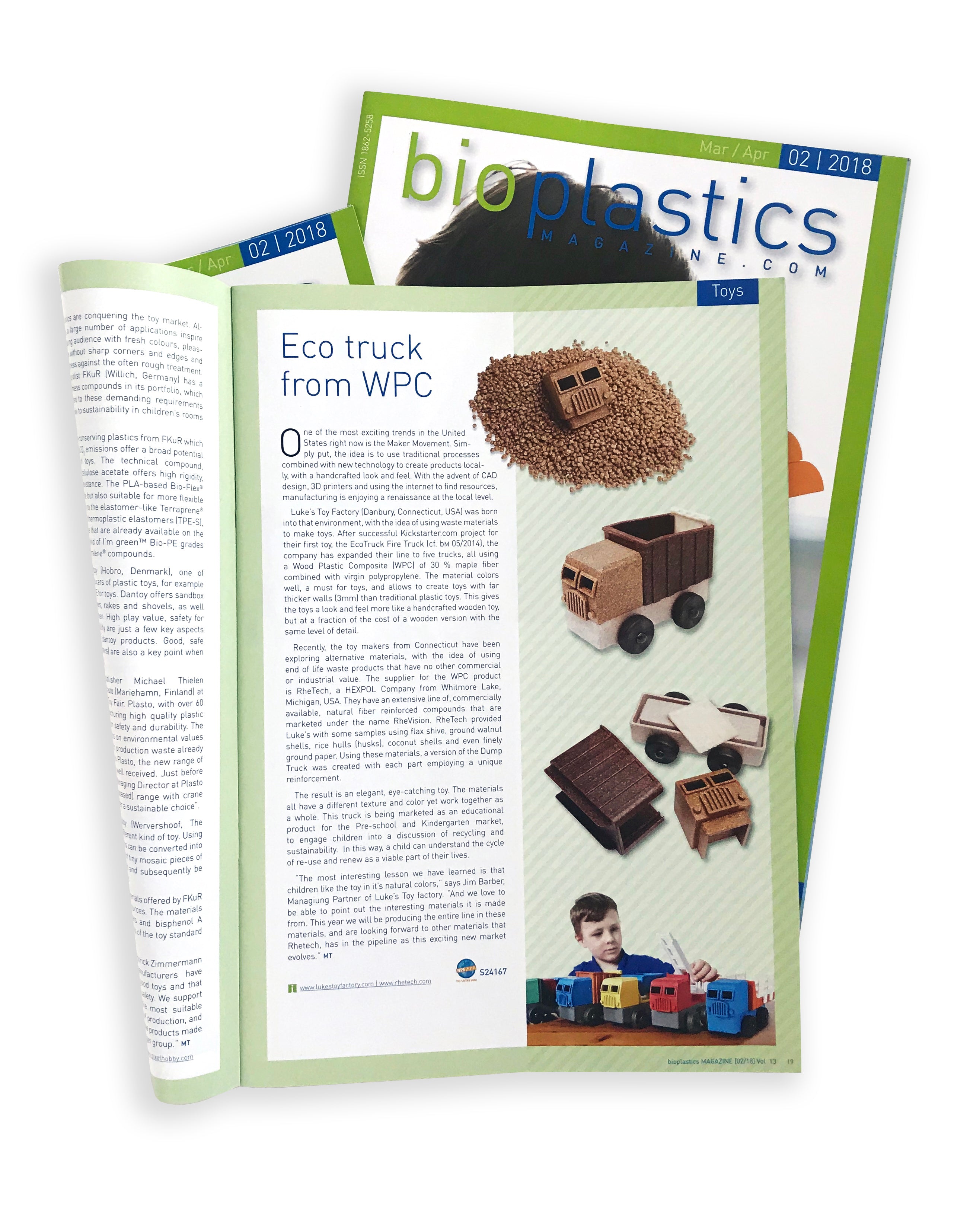

Luke’s Toy Factory was born into that environment, with the idea of using waste materials to make toys. After successful Kickstarter.com project for their first toy, the EcoTruck Fire Truck, the company has expanded their line to five trucks, all using a Wood Plastic Composite (WPC) of 30% maple fiber combined with virgin polypropylene. The material colors well, a must for toys, and allows to create toys with far thicker walls (3mm) than traditional plastic toys. This gives the toys a look and feel more like a handcrafted wooden toy, but at a fraction of the cost of a wooden version with the same level of detail.

Recently, the toy makers from Connecticut have been exploring alternative materials, with the idea of using end of life waste products that have no other commercial or industrial value. The supplier for the WPC product Luke’s Toy Factory uses is RheTech, a HEXPOL Company from Whitmore Lake, Michigan. They have an extensive line of, commercially available, natural fiber reinforced compounds that are marketed under the name RheVision. RheTech provided Luke’s with some samples using flax shive, ground walnut shells, rice hulls (husks), coconut shells and even finely ground paper. Using these materials, Luke’s Toy Factory created a version of their Dump Truck with each part employing a unique reinforcement.

The result is an elegant, eye-catching toy. The materials all have a different texture and color yet work together as a whole. This truck is being marketed as an educational product for the Pre-school and Kindergarten market, to engage children into a discussion of recycling and sustainability. In this way, a child can understand the cycle of re-use and renew as a viable part of their lives.

“The most interesting lesson we have learned is that children like the toy in it’s natural colors,” says Jim Barber, Managing Partner of Luke’s Toy Factory. “And we love to be able to point out the interesting materials it is made from. This year we will be producing the entire line in these materials, and are looking forward to other materials that Rhetech, has in the pipeline as this exciting new market evolves.”