Sustainability is a Journey. Some quick Lessons from a Startup.

Sustainability. It’s a buzz word that is top of mind for consumers, companies, academics, and governments. Carbon emissions, water/electric use, ethical sourcing and labor, supply chains, plastics, recyclability, durability, safety, governance… are all factors in the sustainability of a company and its products or services.

A recent survey commissioned by Unilever found that 78% of American consumers say they feel better when they buy products that are sustainably produced. Three out of four millennials reported a willingness to pay extra for sustainable products. 51% of their parents’ generation reported the same. All of this bodes well for brands that embrace sustainability in an authentic way. But what does this mean for companies looking to capitalize on this seismic shift in consumer expectations and behavior?

As a startup, we’ve come to realize that “sustainability” is not an end-state to be achieved. It certainly does not occur overnight. The pursuit of sustainability for a brand and its products is a journey - even for the biggest companies. Iteration and constant improvement are required at every stage, in every facet of the business. What might have been considered a breakthrough or a major accomplishment six months ago might today, need to be refined, changed, or in some cases, completely overhauled.

Luke’s Toy Factory started as an idea back in 2007 in response to high-profile recalls of lead tainted toys made on the other side of the planet, in China. At the time, we simply thought there must be a better, safer way to make toys. Over a decade later, we are now seeking to redefine how, where and from what material basic educational toys are made. Here are some lessons from our journey thus far in sustainability. It is a journey we believe we are only just beginning.

1. Prioritize - As a children’s toy company, safety is our #1 priority. Full stop. It doesn’t matter how fun, educational, or sustainable a product is - if it isn’t safe, it isn’t viable. Our north star of safety informs Luke’s designs and the materials we are able to use - and therefore, the sustainability of the toys we make.

2. Be a contrarian - Inherent in a shift toward sustainability is the necessity to go against the status quo. 85% of toys are made in China. We felt that to ensure safety and quality, manufacturing should be done here in the U.S. Stateside production also enables far shorter supply chains - good for the environment (in terms of CO2 emissions), and the bottom line of our wholesale customers who are able to place smaller orders on-demand, rather than a massive order once or twice a year.

3. Break the rules - Modern technology, chemistry, and manufacturing methods are a catalyst for innovation and sustainability. Put them to use. The science and equipment behind the injection molding of plastic hasn’t changed much since the 1950’s. When we approached twenty injection molders across the U.S. with the idea of compounding sawdust with plastic, they told us it would ruin their machines. Eventually we were able to find a vendor willing break the rules with us, and give this new material a shot (ahem - that’s an injection molding pun) ... And it worked.

4. Design for durability, reusability, and recyclability - Something you use once and throw away… not sustainable. Something you can use over and over again, and then pass down to another generation… that’s sustainable. Long-lasting design is one of five sustainability factors highlighted in KickStarter’s Sustainability Resource Center, in which Luke’s Toy Factory is featured. By incorporating sawdust, we are able to save the organic waste material from being incinerated, and it enables us to use 30% less plastic than traditional plastic toys. The sawdust also allows us to make parts that are robust and durable, meaning our toys survive years in a playroom or classroom before being passed down, donated, or put on the shelf as decoration.

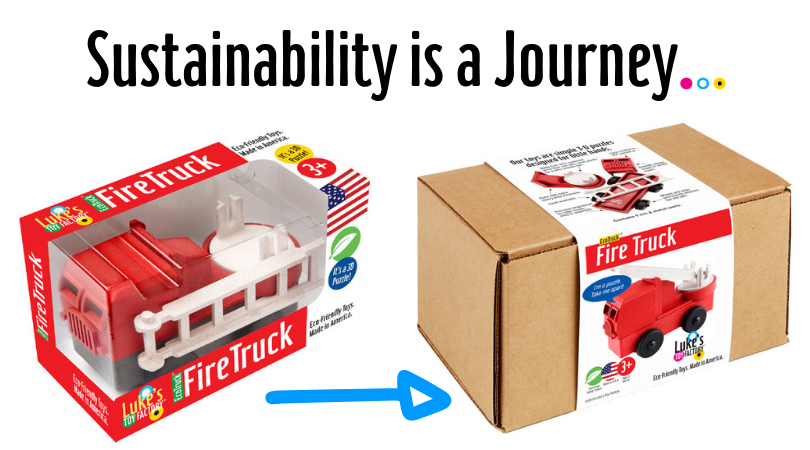

5. Learn, Iterate, and Improve… constantly - there really is no end state for sustainability. There is always room for improvement. We’ve completely overhauled our packaging three times in five years, with the goal of eliminating all single-use plastic. Today, our toys come in boxes made entirely from recycled paper and cardboard.

Still, we’ve heard from some toy store owners that customers prefer earlier packaging with a clear single-use plastic shell because it allowed them to see the toy.

Clearly we still have our work cut out for us both in production and communication ... to that end we’ll have some exciting news to share soon! In the meantime, we hope you’ll take this sustainability journey with us.